WELSONMOLD owns the high-level mold design team and invests gradually in technical training every year to make the design level to be in line with the international standard.In order to shorten the lead time of the mold development and designing, WELSONMOLD has introduced the professional CAD/CAE/CAM software like AutoCAD, Unigraphics NX, Moldflow and Pro ENGINEER with the different assignment. Moreover, WELSONMOLD can make turn-key solutions from the concept to molding production,according to the different requirements for cost budget, material properties, precision, manufacture lead time, the efficiency of the mass-production and daily maintenance.

.jpg)

.jpg)

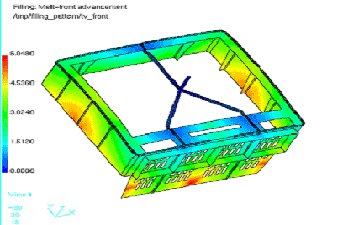

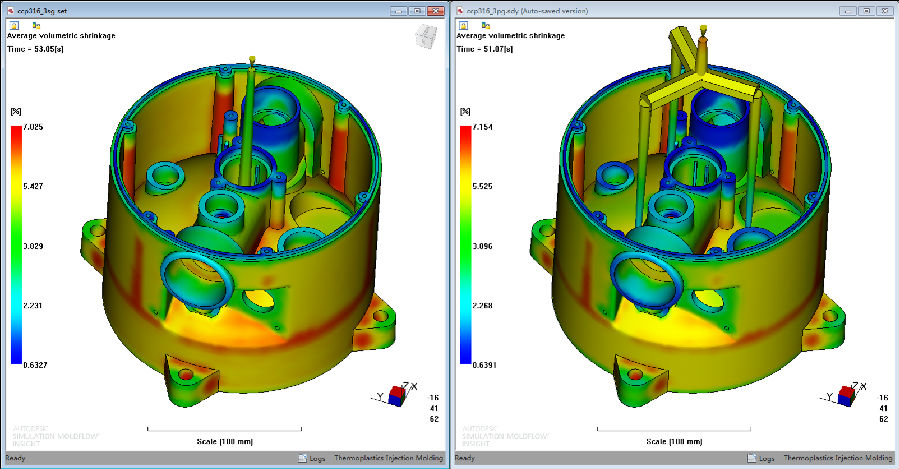

Mold Design Optimization:

ŌĆó BestGate location, Runner & Gate sizing

ŌĆó Tonnage Optimization

ŌĆó Cooling Layout, Cooling Insert

ŌĆó Determination of part warpage and corrective measures to reduce warpage.

ŌĆó Cold runner / Hot runner business case

Product Design Optimization:.png) ŌĆó Part Thickness Optimization

ŌĆó Part Thickness Optimization

ŌĆó Balanced Filling

ŌĆó Clamp tonnage optimization thru product design

ŌĆó Rib and Boss Design

ŌĆó Design for manufacturability

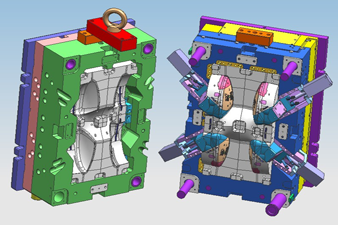

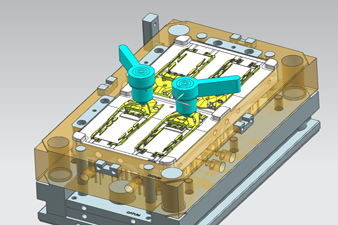

Complex Mold Design:

ŌĆó Precision mold

ŌĆó Double injection mold

ŌĆó Overmolding mold

ŌĆó Hot & cold runner system mold

ŌĆó Insert tooling

ŌĆó Unscrewing mould

ŌĆó Gas assisted mold

ŌĆó Large size mold

ŌĆó Multi & single cavity mold

ŌĆó Quick change molds

ŌĆó Multiple slide action molds

ŌĆó Rapid delivery precision mold tooling

.png)

.png)

.jpg)

.jpg)

+86 755 27819800, 27309875

+86 755 27819800, 27309875 +86 755 27309877

+86 755 27309877