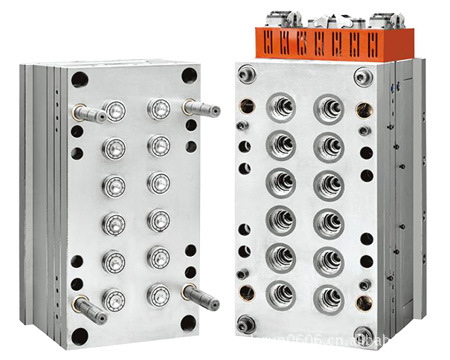

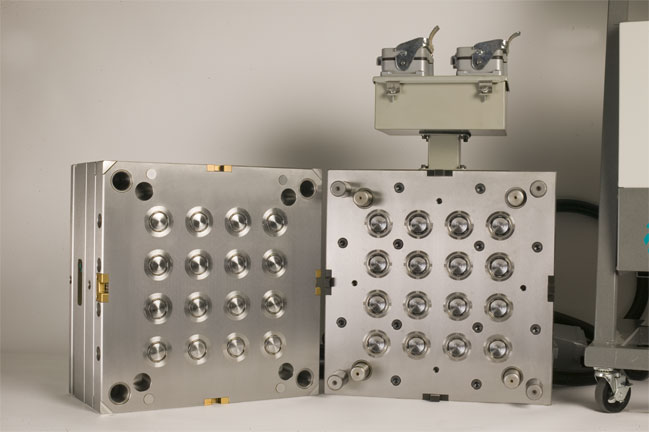

Multi Cavity Mold

A mold with multiple cavities of the same part that is typically used to reduce piece-part pricing for higher volume parts. Multi-cavity molds are particularly economical in mass production of high quality components. If you want more than tens of thousands of parts per month, then a Multi-Cavity Mold is for you. What you are really buying is machine time. So the less machine time it takes to mold your parts, the less your parts will cost.

Our Multi Cavity Mold Service

When focusing on the development of high-processing molds, high output-quantities with a maximum of availability is a philosophy of Welson Mold. Guaranteed exchangeability of all components make Welson Mold injection molds suitable for worldwide application.

If you want more than tens of thousands of parts per month, then a Multi-Cavity Mold is for you. We actually recommend more than a single cavity mold when the capacity is going to be greater than 40,000 pieces a month. We also recommend going to a multiple cavity mold when the customer is trying to meet a certain price point. But if you do go with multiple cavities, know that your larger investment in molds gets rewarded with lower piece prices.

Optimize your multi-cavity mold design

When moving from single-cavity to multi-cavity tooling, it’s important to recognize that parts that behave perfectly in a single-cavity mold might not play well with others, at least not without first making some adjustments or tweaks to the part, the process, or even the material. Optimize your multi-cavity mold design by:

- adjusting the mold gate

- using side-actions

- including pickouts

- using a family mold

- opting for liquid silicone rubber.