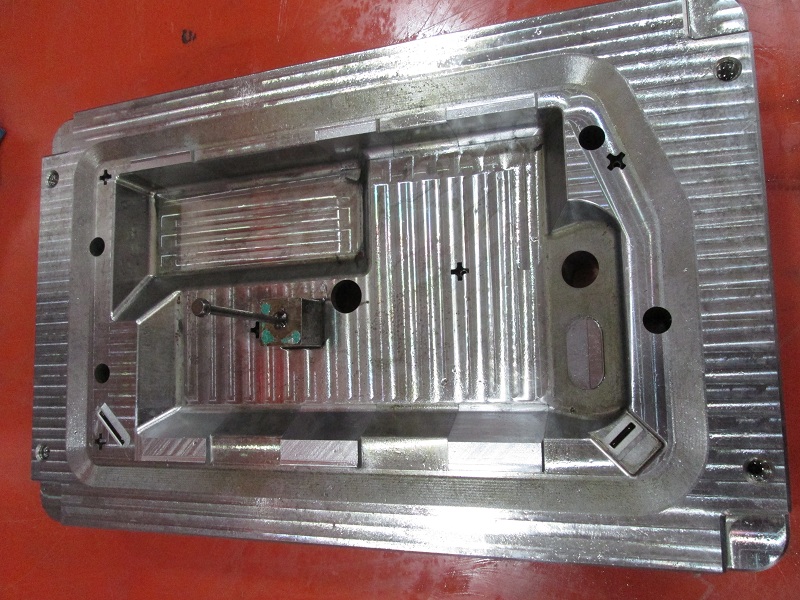

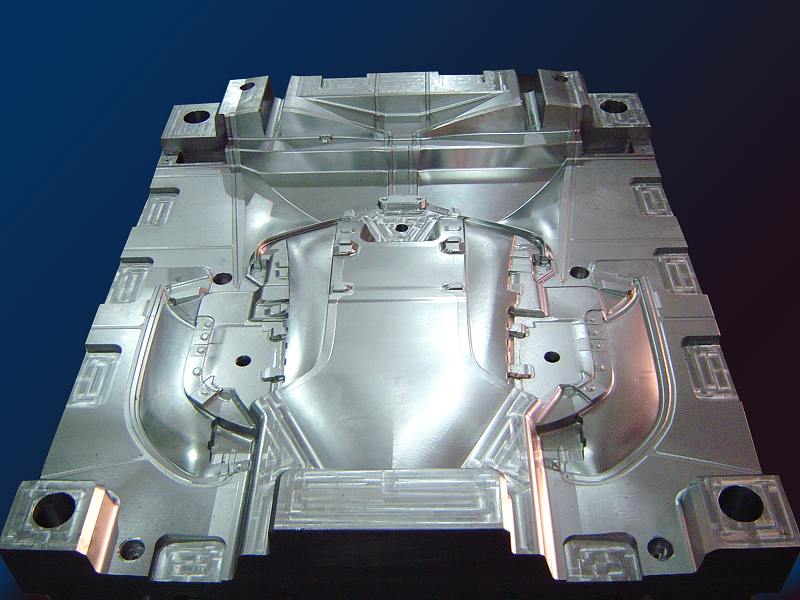

Mold Inserts

Inserts are parts of the mold that are created separately from the mold cavity block. Inserts are inserted in the block to achieve a desired cavity shape or cooling effect. An insert will only assist heat transfer if a cooling channel is located in or near the insert. Inserts can be used to modify the rate of cooling in specific areas of the mold.Our Mold Inserts Manufacture Service

Welson mold’s mold inserts are designed and manufactured to exceed demanding customer expectations for quality, reliability, and performance. With an extensive product selection supported with superior customer service, you can count on Welson Mold to meet your needs.

Tight-tolerance injection molded inserts from Welson Mold offer:

- Flat and parallel rolled or machined ends for a complete seal to prevent seepage during the ID

- Knurled or indent pattern on the OD can often be used to help reduce the molding cycle time and to prevent distortion as the part is injected

- Chamfer details can be designed to seal off the mold flush on the OD and create a lead edge on the ID for improved bolt location

- Can use range of materials or may be plated for corrosion resistance

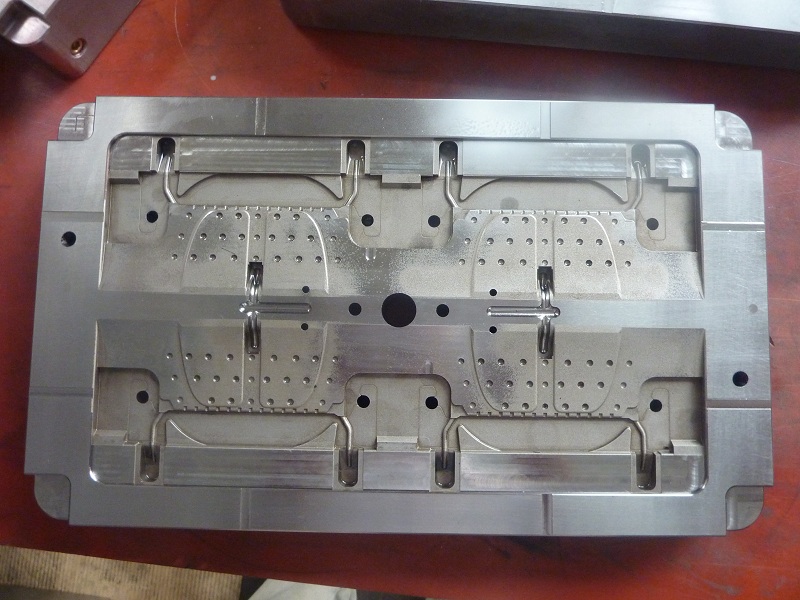

Mold Inserts Features and Benefits

- Space and weight savings

- Controlled minor diameter reduces insert movement during molding and assures accurate alignment

- Insert flange provides a large bearing surface which is advantageous during molding process and final assembly

- Insert design ensures optimum strength performance