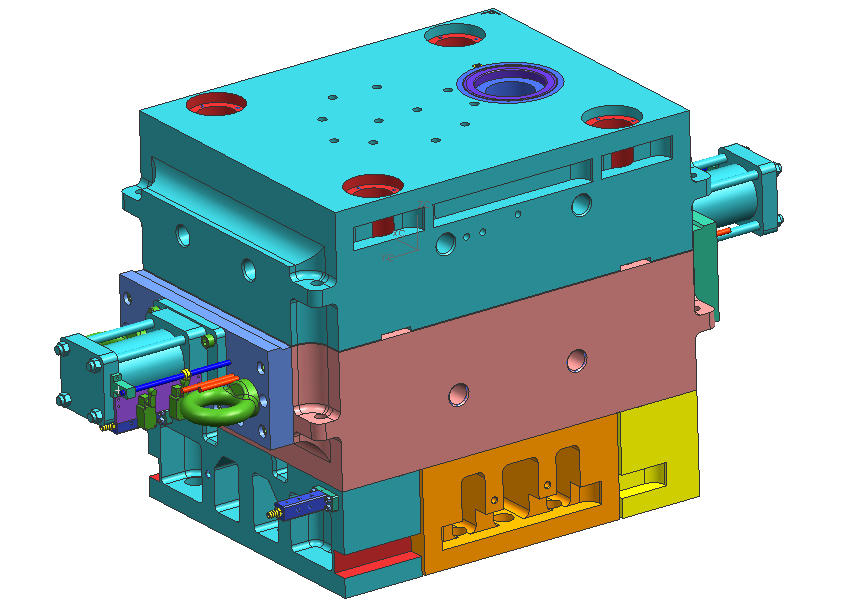

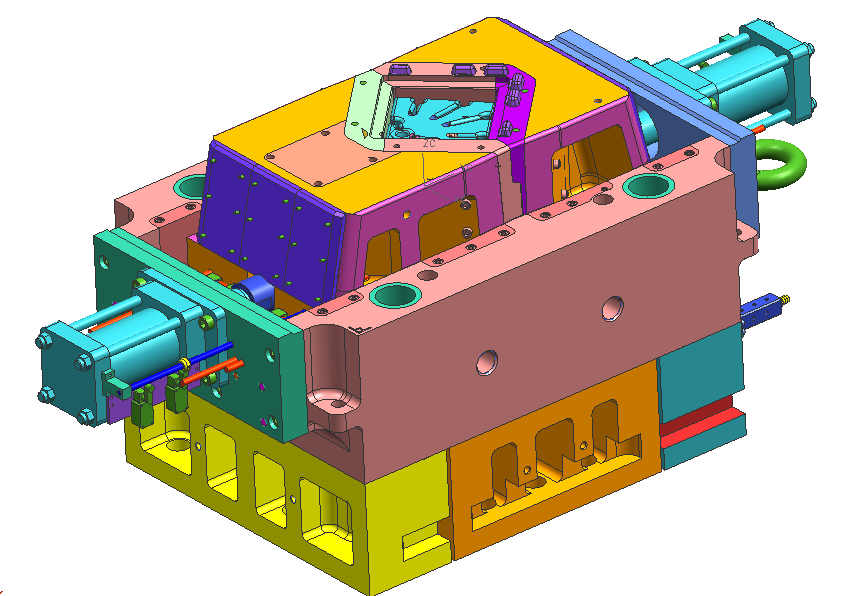

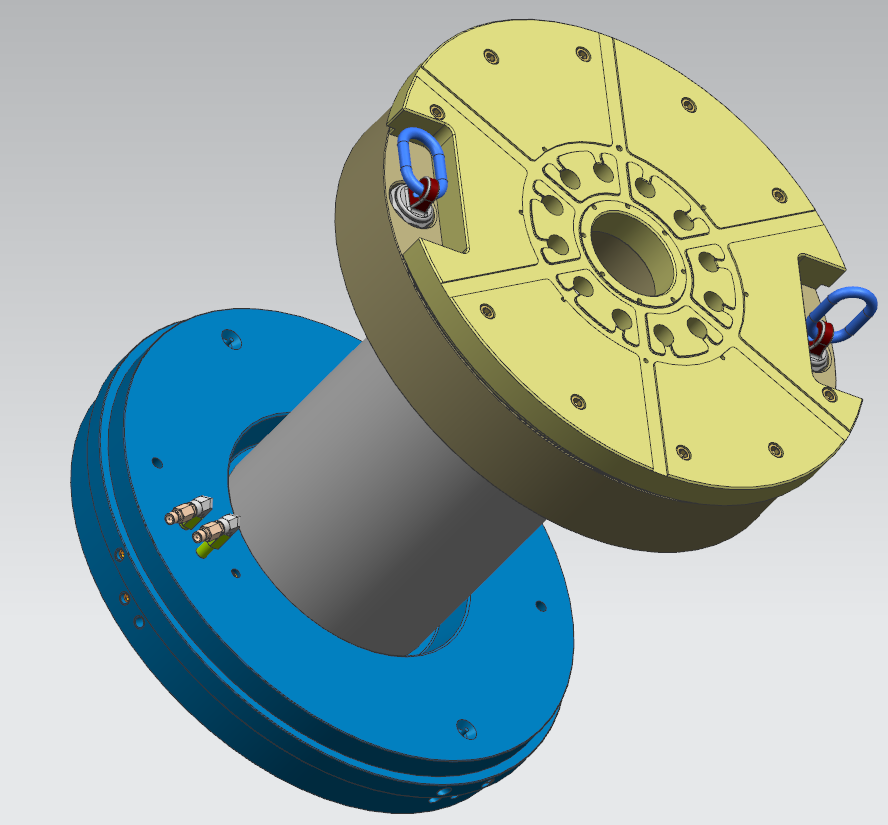

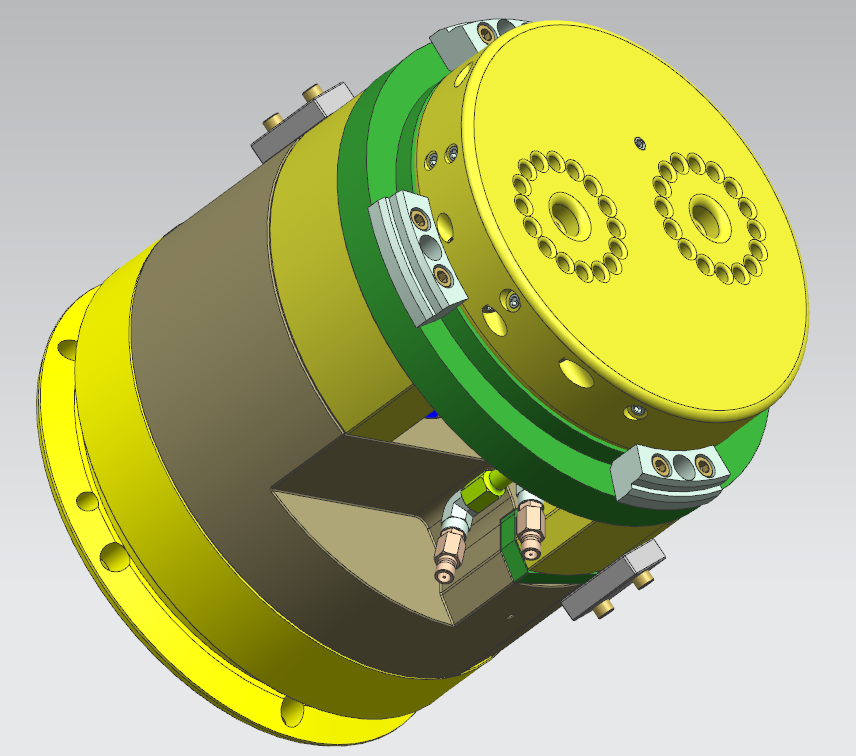

Die Casting Mold

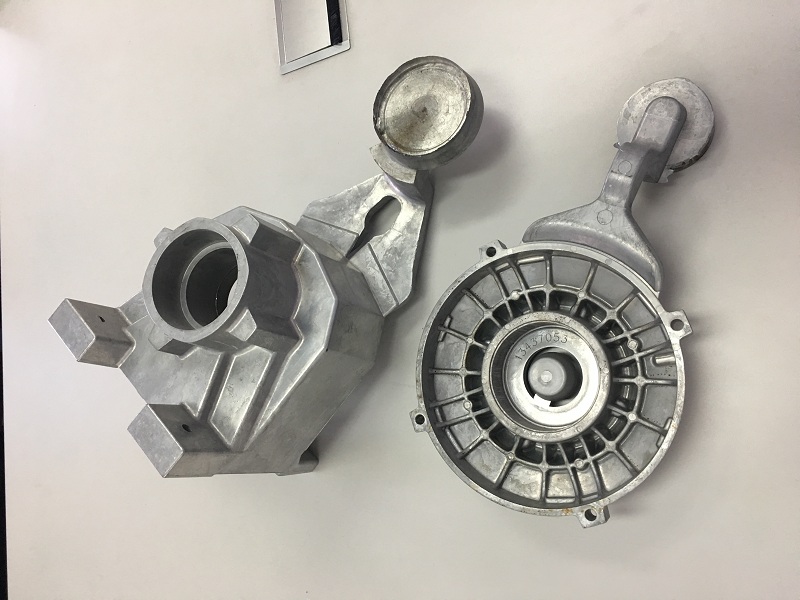

Die casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface metal parts. It is accomplished by forcing molten metal under high pressure into reusable metal dies. The process is often described as the shortest distance between raw material and finished product. ‘Die casting’ is called ‘pressure die casting’ in Europe.

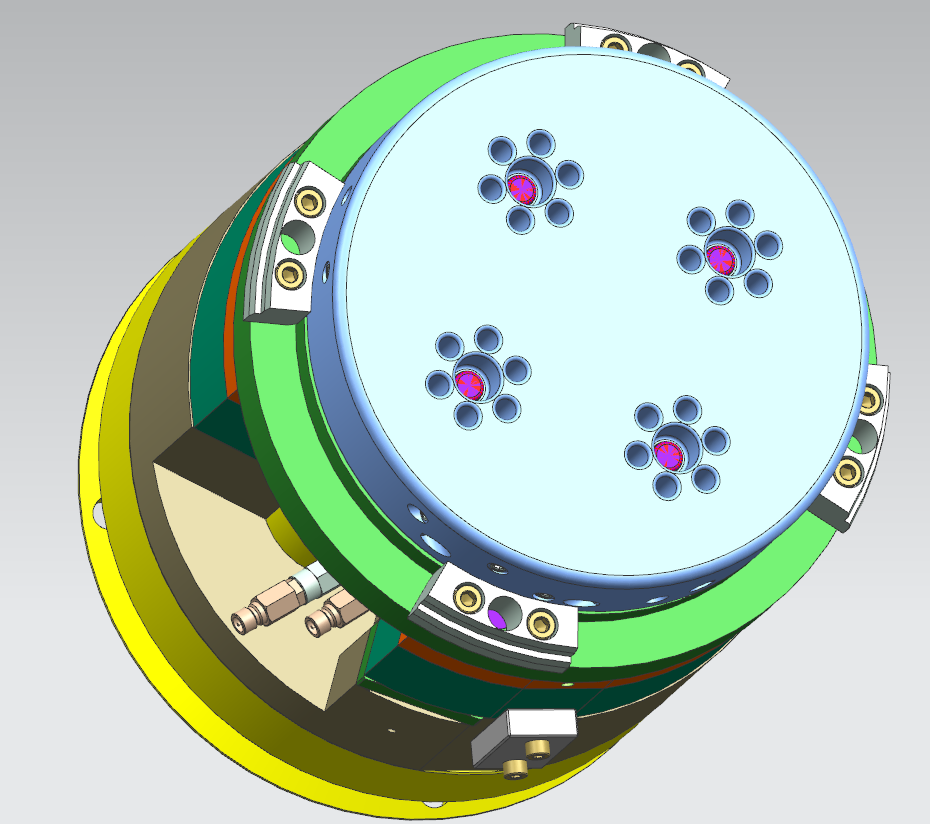

Our Die Casting Mold Service

In a process similar to injection molding, we use certified machines and pressure casting dies to form molten metal into your designs. Our pressure die casting process is effective and very reliable. This method can actually end up saving you money.

The majority of our castings are made from zinc, copper, aluminum, magnesium, lead, pewter, or other tin-based alloys. Because of our flexibility, we can accommodate any need you may have – from small batches of 50 to as many as 1,000 pieces. Since die casting mold tooling can be more expensive and difficult to make, this method is suited for larger production runs, keeping the price for parts produced lower.

Die Casting Mold Benefits

Welson Mold engineering design experts will support all your needs. including:

- Die casting aluminum or zinc metal selection

- Design improvements

- Die casting prototypes

- Mold flow analysis

- Die casting molds

- Die casting tolerances

- Machining and fixtures

- Surface finishing and assembly