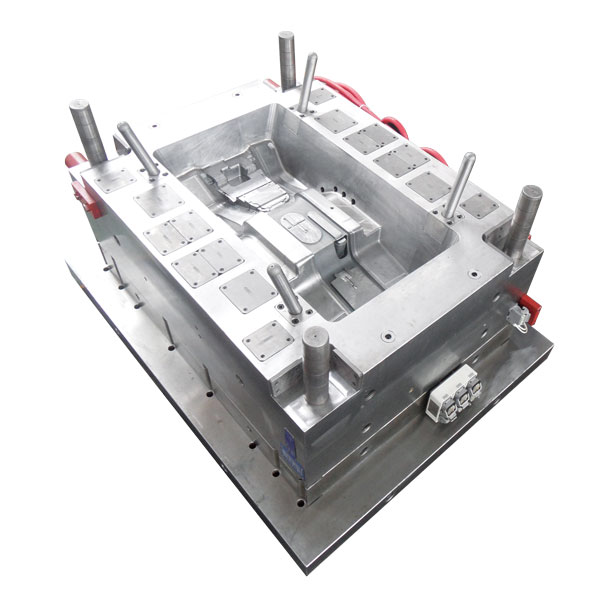

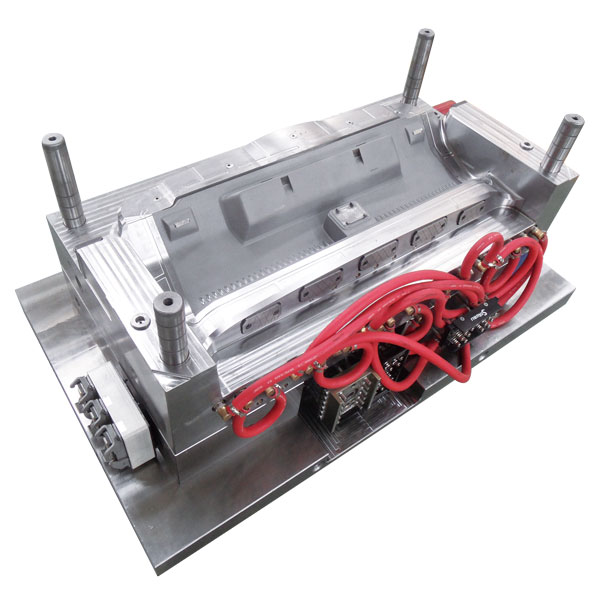

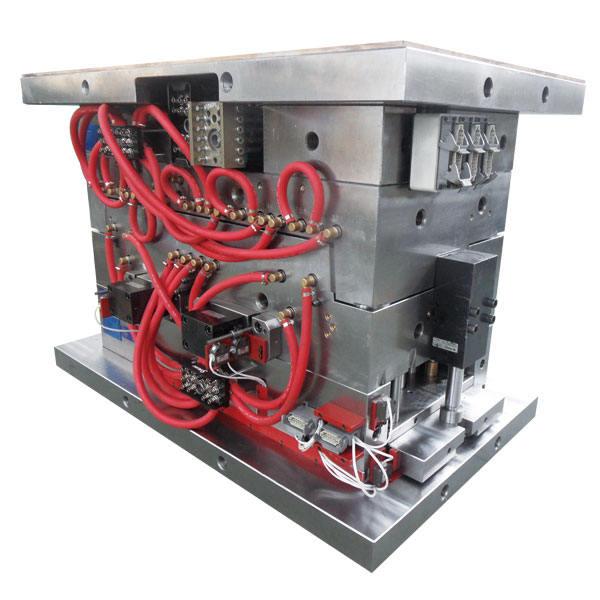

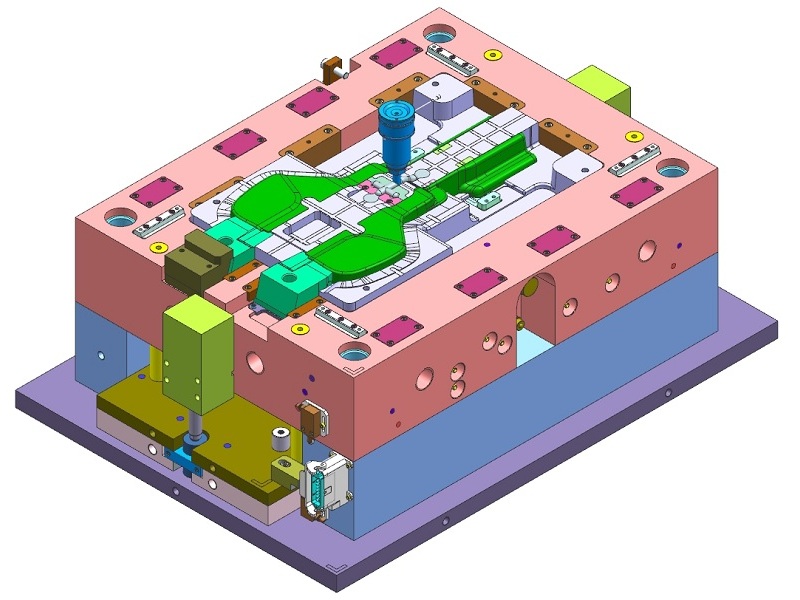

Large Part Mold

Very large moldings, and in particular those with thick cross sections, require extremely specialized heavy duty presses, unique rubber formulations and highly specific production techniques and methodologies. Experience in the unique material compounding techniques is required for the molding of very large articles.

Our Large Part Mold Service

When it comes to large plastic parts, shipping, part handling, cosmetics and cost are some of the challenges. Welson Mold experience, equipment, technology and innovation address these challenges!

Depending on part features, cosmetic requirements, and production volumes, we employ robotic automation with customized end-of-arm tooling to enhance efficiency and reduce the need for operator intervention. Our large molding presses are connected to customized, computer controlled automated drying and blending equipment that provides efficient and reliable delivery of feed stocks for optimized efficiency and quality.

Large Part Mold Applications

Component consolidation and technology advancements continue to expand the range of applications and industries employing Welson Mold injection molded large plastic parts, including:

- Outboard marine motor covers

- Agricultural equipment, ATV and off road vehicle hoods and fenders

- Lawn and garden riding mower hoods

- Plastic pallets

- Housings

- Appliance components and panels

- Instrument panels

- Impeller and fan blades

- Irrigation components