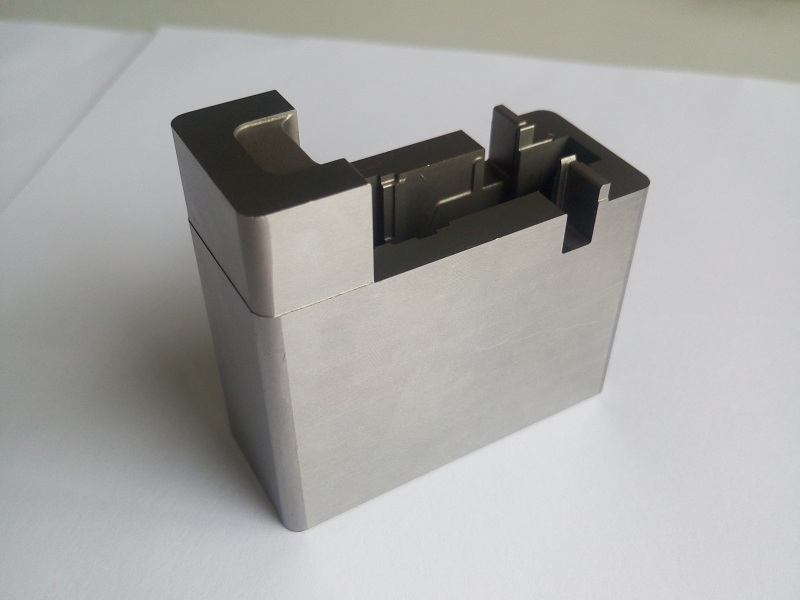

Precision Component

Machining is the fastest, most economical way to produce a finished technical plastic component – particularly for small production runs. Plastic injection molding creates precision thermoplastic parts to mold exact shapes and features for use in any application. Engineers, designers, machinists, and production coordinators all played critical roles in the success of a project.

Our Precision Component Manufacture Service

Welson Mold looks back at decades of experience in the machining of engineering and high-temperature plastics. Equipped with state-of-the-art technological facilities, our highly qualified team of specialists manufactures precision components to the very narrowest tolerances.

We expertly machine precision plastic components for a variety of customers in nearly every industry including; parts made for medical, electronics, instrumentation,and industrial uses.

Precision Component Features and Benefits

- Capable of manufacturing to very fine tolerances of extremely small parts and components, measuring as small as 1cm3 and weighing 0.1 to 0.01 grams or less

- Increased design flexibility as precision molding allows for unlimited configurations