Unscrewing Mold

Unscrewing molding is a unique injection molding process with mold technology that includes movement and rotation to produce threaded components. Some plastic parts such as caps and closures with detailed threads cannot be removed using standard knock-off methods. After they are molded, parts need to be carefully unscrewed from mold to avoid damaging the threads.

Our Unscrewing Mold Service

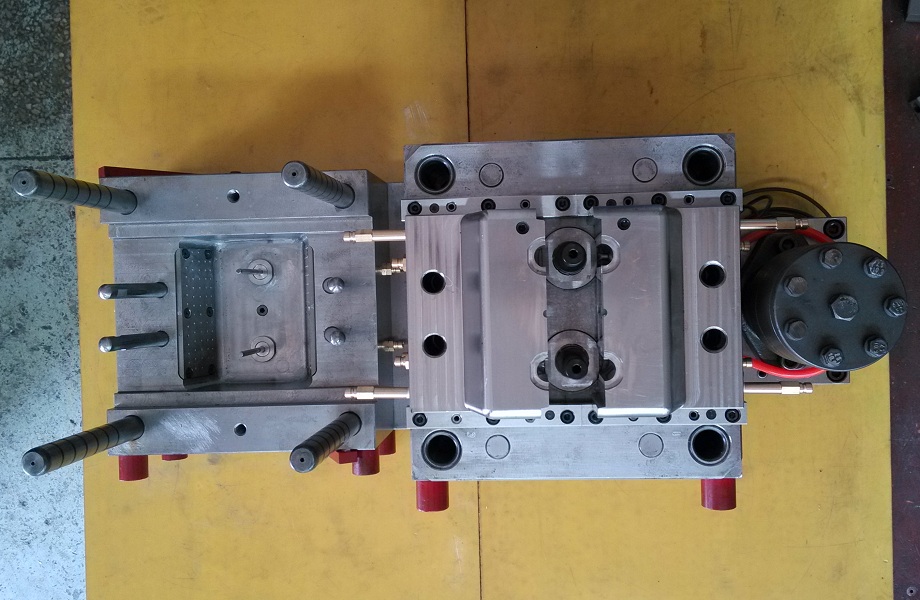

Welson Mold manufactures high quality unscrewing plastic injection molds for threaded parts. We can produce high quality long lasting molds that can increase your speed, productivity and accuracy with higher cavitations and faster cycle times.

Because these threaded plastic parts are typically needed in high volume applications for items such as bottle caps or cosmetics packaging, the unscrewing plastic injection mold most operate at a high speed to reduce cycle times thus reducing part costs. The unscrewing plastic injection molds must also be high quality and reliable to operate for a large number of cycles while only needing routine preventative maintenance. Welson Mold unscrewing molding equipment provides the speed and productivity to produce threaded plastic parts economically.

Our experience includes the use of various rotating core drive mechanisms like, hydraulically driven racks, servo motor drives, planetary gear drives and hydraulic rotating motor drives.

Unscrewing Mold Applications

Unscrewing Molds are used to produce parts with internal or external threads, such as:

- Nuts and Bolts

- Sprinkler Heads

- Bottle Caps & Closures

- Personal Care /Cosmetics

- Medical/Pharmaceutical

- Consumer Goods

- Automotive Parts